Last week we discussed Hazard Communication, Part II.

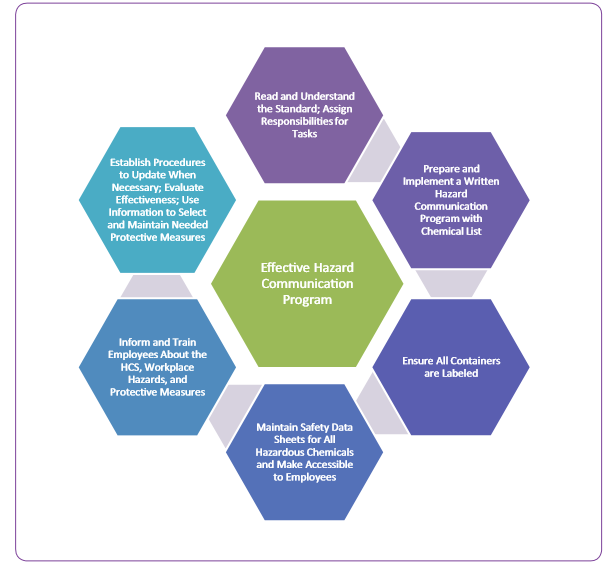

This week we are going to discuss Step 4 for creating a Hazard Communication program.

Step 4) Maintain Safety Data Sheets

As part of the Hazard Communication Standard, OSHA requires chemical manufacturers and importers to obtain or develop a safety data sheet (formally known as Material Safety Data Sheets or MSDSs) for each hazardous chemical they produce or import. Employers are required by OSHA to have an SDS in the workplace for each hazardous chemical they use and to provide SDS training for their employees.

Many manufacturers and suppliers make their SDSs available on the internet. If you do not have an SDS for a chemical used at your worksite, contact the manufacturer. Before using any SPF product, you and your employees should read and understand the entire SDS for any product you may come in contact with at a worksite.

The SDS contains very important information about the product, including:

- The chemical constituents and the approximate concentrations

- The PPE appropriate for the job

- Information on how to handle accidental spills/releases

- And, information on storage, handling, transportation, and disposal.

This is documented in a 16 section format with the following sections included:

- Material Identification

- Hazard Identification

- Composition and information on ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and storage

- Exposure control and personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

This information is intended to help several audiences – employers, workers, safety and health professionals, emergency responders, government agencies and consumers.

Because these documents are so important, make them as readily accessible at a job site as possible. Keeping one clean copy of each SDS in a clearly marked binder is a good practice that helps keep the information readily accessible. Many contractors like to keep several spare copies of SDSs on hand, in the event of an emergency or incident, this allows multiple copies to be available for emergency responders. Another good practice is to review the location of the SDS binder with all workers on the SPF jobsite before the job begins. Note that OSHA requires that all SDSs be readily available to all workers at the jobsite, which may include other trade workers.

When they visit, OSHA compliance officers will look for the following in your program:

- Who is responsible for obtaining and maintaining SDSs?

- How are SDSs maintained and kept in the workplace?

- How do workers obtain access to them in their work area during the work shift?

- Procedures to follow when SDS is not received at the time of first shipment

- SDS for each hazardous chemical in the workplace

- And, training of workers, including review of the SDS format and use

Additionally, many SDSs are now available online, so workers with mobile devices or in-truck internet service may be able to access them electronically on site. Also, it may be possible to obtain the SDS in multiple languages if needed. Contact the material manufacturer for more information.

Stay tuned next week as we discuss Steps 5 & 6 of creating a hazard communication program.

Subscribe here to keep in touch with Spray Foam Advisor and get your FREE copy of 25 SPF Frequently Asked Questions and a PRIVATE link to Robert Naini’s SPFA Breakout Session, “3 Ways to Close More Sales with Building Science.”