Last week we talked about processing closed cell foam and learned some general processing guidelines. This week let’s discuss poor quality foam, how to identify it and how to trouble shoot spray foam application.

There are several types of poor quality foam that can be created and they fall into a few categories:

- Off-ratio foam

- Shrinking foam

- Voiding foam

Let’s start with off-ratio foam. We know that spray foam is made by mixing equal parts iso and resin together at the gun and spraying that mixture onto the substrate; but sometimes these two components do not mix in equal quantities and this is called off-ratio foam. There are two types of off-ratio foam: iso-rich foam and resin-rich foam, and visually identifying which type of off-ratio foam is present is the first step in troubleshooting.

So what does off-ratio foam look like?

Iso-rich foam is dark in color and crispy, often referred to as friable and as the name infers, it has too much iso and is missing resin. Resin rich foam has a powdery white or cream color and is soft and sticky, it has too much resin, is missing iso and does not fully cure. Both off ratio scenarios can limit the expansion and rise of the foam; keep an eye on the wall as you are spraying because noticing these problems will help you identify the solutions, and as you gain more experience, identifying these issues will become easier. When you see a problem like this STOP spraying, DO NOT keep pulling the trigger thinking the problem will go away and it will solve itself; it will not and that will cost you money in the long run.

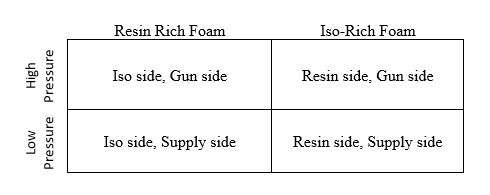

How do we solve these problems when they occur? First we have to identify the problem, the beauty of using a single drive proportioning system is that it makes troubleshooting very easy, this design will allow us to split the system into four sections or quadrants that will guide us toward the most likely problems and their solutions.

We will begin by identify the material on the wall, this material looks dark and crispy. That means we have iso on the wall. If we have plenty of iso that means we have a problem on the resin side of the machine, so we can ignore the iso side, because iso is not our problem, and we look at the resin gauge. Is the current pressure higher or lower than our set pressure? If it is lower, that means we have a supply side problem, the machine is not building pressure. We have iso-rich foam on the wall and low pressure on the resin-side, so we know that the problem exists on the resin supply side, at the back of the system. What type of problems could we have?

We could be out of material in the resin drum, such as a cavitation of the supply pump in the resin drum or the supply pump may have stopped working, due to a loss of air or disconnection.

Let’s look at another example:

First, we have to identify what is on the wall? If the material is powdery white or cream color and is soft and sticky, that means we have resin rich foam on the wall, so we have plenty of resin and not enough iso. Now we look at the iso side pressure gauge and we see the current pressure is higher than our set pressure. So we have resin-rich foam on the wall and high pressure on the iso side; so we split the machine into quadrants, we know the problem is on the iso side, because there is plenty of resin, this eliminates the resin half of the system. And high pressure on the iso pressure gauge means we are building pressure and the problem is on the gun side.

If we identify the problem on the iso-side, at the front of the system, or the gun side, what type of problems could we have? Typically this will be a restriction in the gun, more often than not clogged screens or you could also have a blockage inside the gun block; make sure you clean the gun thoroughly.

This general troubleshooting logic can be used to split your system into quadrants and to identify where to start your investigation.

Stay tuned next week as we discuss shrinking and voiding foam in Troubleshooting SPF, Part II.

Subscribe here to get your FREE copy of 25 Spray Foam Insulation Frequently Asked Questions from Spray Foam Advisor.